This makes these motors a good fit for medical, biotech, security and defense, and semiconductor manufacturing applications. Stepper motors also tend to be compact and inexpensive. To summarize, stepper motors are good solutions for applications with low speed, low acceleration, and low accuracy requirements. As a result, a stepper motor can be up to an order of magnitude less expensive than a comparable servo motor. Because of the high pole count and their ability to generate holding torque, they consume less power at zero speed. Stepper motors typically don’t require feedback, they use less expensive magnets, and they rarely incorporate gearboxes. The discussion above brings us to a final key differentiation between stepper axes and servo axes, which is cost. Still, at these resolutions, even a 200-step move corresponds to a fraction of a degree. Although we command stepper motors with a resolution of typically between 25,000 and 50,000 counts per revolution, because the motor is a spring-mass system under load, our typical resolution is 2000 to 6000 counts per revolution. If the drive commands a motor to advance 200 steps, however, it will do so to within just a few steps, which at that point represents an error of a few percent. As a result, a command to advance by five steps may only result in the motor turning four steps – or six. The motor needs to break friction to begin turning and move the load, at which point the rotor is not fully controlled. You can think of a stepper motor as a spring-mass system. Stepper motors also have performance limitations. As a result, it is unusual to find stepper motors capable of producing more than 1000 to 2000 ounce inches of torque. Stepper motors generally are not available in frame sizes larger than NEMA 34, with most applications falling in the NEMA 17 or NEMA 23 motor sizes.

They are compact and generally economical (see figure 1). The high pole count allows them to generate very high torque at zero speed. Because they generate incremental motion, they are generally run open loop, eliminating the cost and complexity of an encoder or resolver. Stepper motors have a number of positive attributes. Because of the very high pole count, the motion appears to be continuous.

High torque servo motor arduino driver#

The stepper motor driver energizes each pole in sequence so that the rotor turns in a series of increments, or steps. Stepper motors feature very high pole counts, typically 50 or more. When current runs through the stator windings, it generates a magnetic flux distribution that interacts with the magnetic field distribution of the rotor to apply a turning force. Stepper motors consist of a rotor with permanent magnets and a stationary stator that carries the windings. The decision tree for choosing between the two has many branches but the most important are speed, acceleration, and price target. When properly applied, however, both stepper motor and servo motor can provide effective, reliable power for a highly successful system. That holds particularly for servo motors and stepper motors.

High torque servo motor arduino full#

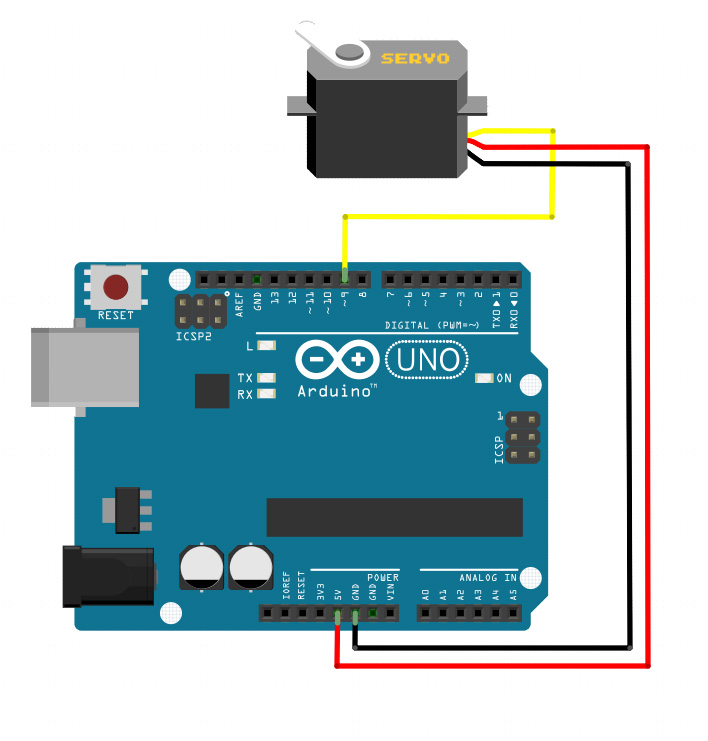

It sets the speed of the servo with 0 being full-speed in one direction, 180 being full speed in the other direction and 90 being no movement.It is an engineering truism that there is no perfect solution, just the best solution for the problem at hand. One of the most important functions is the servo.write(speed). On board other than the Arduino Mega, using the library disables the PWM functionality on pin 9 and 10 regardless of whether the servo is connected to those pins or not. There is a library in Arduino called servo.h that includes some useful function for controlling the servo motor and can support up to 12 motors on most Arduino boards.

Most servo motors come with a set of accessories. We used a continuous rotation in our project Cheers as we need a high torque motor that can operate at near zero speed without releasing much heat. Continuous servo motor does not have a limit on its range of motion, so instead of the having the input signal determine which position the servo should rotate to, it relates the input to the rotary speed and direction. It uses internal electronics to identify the current angle of the motor and Arduino and the servo.h library can be utilizied to turn the motor to a given angle within the range of rotation. The former is a geared down motor that has limited range of rotation. There are two kinds of servo motor, standard and continuous. A drive is used to collect the feedback from the sensor to precisely control the position of the motor. It consists of a motor and a sensor for feedback position. A servo motor is a rotary actuator that allows for precise control of angular position.

0 kommentar(er)

0 kommentar(er)